THE FOUR (4) PRINCIPAL REASONS FOR USING DOCK LIFTS ARE AS FOLLOWS:

Safety: The most common ways to move goods between truck beds and ground level are simply manhandling them from one level to another or by unstacking pallets on the truck, using skate conveyor to roll the goods to ground level, where the goods are restacked on pallets for further movement. This method is illustrated on the “Click here for cost of injury” box above. Clearly these methods pose a great risk for back, shoulder and hand injuries which can be very expensive. With a loading dock lift, operators are standing on a level surface while goods are moving from truck height to ground height, with no heavy lifting, twisting or turning. Using dock lifts is simply a much safer operation.

Efficiency: Two men with pallet jacks can unload a 53 foot trailer using a loading dock lift in less than half (1/2) the time it would take them to do the same job with skate conveyor in an unstack and restack operation.

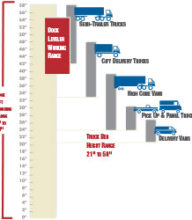

Versatility: Dock lifts are the only kind of off-loading equipment that can service any size truck from low step vans to high reefer semis. (See the “Click for range” box above.) Dock levelers in concrete docks are limited to small operating ranges and can become obstructions for non-conforming vehicles. Dock lifts can also provide dock to ground access when loading docks are involved and can easily accommodate reverse operations where heavy goods need to be moved from ground level up to truck beds. Loading dock lift gates do it all.

Cost: The cost of a dock lift should be compared the sum of the following costs:

- The cost of one or more workmen’s compensation injury claims

- The opportunity cost of lost dock workers time due to slow dock operations

- The cost of capital in idle truck time caused by slow unloading times

- The risk of damaged goods in manhandling operations

- HVAC costs incurred due to open doors during excessively slow dock operations

TAILGATE LIFTS VS. DOCK LIFTS

SOME PEOPLE HAVE SUGGESTED THAT TAILGATES ARE A VIABLE ALTERNATIVE TO DOCK LIFTS. WE DISAGREE FOR THE FOLLOWING REASONS:

- Although the initial cost of a tailgate is about the same as a dock lift, the annual maintenance of tailgates is far more expensive.

- The tailgate equipped truck is only good for one vendor whereas the dock lift can benefit operations with any size truck from any vendor.

- The tailgate installation on a truck reduces truck capacity by up to 3,000 lbs. and increases wear on the vehicle, which increases truck operating costs that are usually passed on to the customer.

- Dock lifts are equipped with handrails while the small platforms on truck tailgate lifts rarely have any kind of handrail and therefore greatly increases the risk of the operator falling.

Loading dock lifts have greater utility, are much safer and far less costly than tailgate lifts.

SAVE MONEY

KEEP YOUR DOCK OPERATIONS ON THE LEVEL WITH AN ADVANCE DOCK LIFT