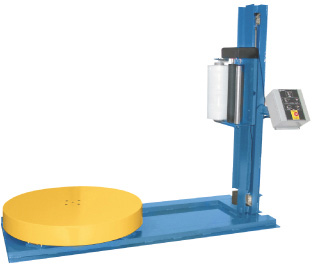

These are our most economical and basic models that are suitable for low volume stretch wrapping operations. These turntable stretch wrappers offer a giant step up in safety and productivity from simply walking around a load with a roll of film in hand. The cost/benefit ratio of these basic turntable stretch wrapping machines is very attractive. Inquire about our pallet wrapping turntables today!

MODEL 100

- This is a basic turntable pallet with footswitch control. This allows the operator to stand in one place while holding the film roll.

In addition to these manual pallet wrappers, we also offer Semi Automatic Stretch Wrappers.

SPECIFICATION TABLE MODEL 100

| Model | Capacity | Load Size | Table Height | Table Diameter | Max RPM | Standard Voltage | Ship Weight |

|---|---|---|---|---|---|---|---|

| ** SW100L40 | 4000 | 52 x 52 | 3 – 1/4 | 60 | 8 | 115/60/1 | 950 |

| SW100H60 | 6000 | 52 x 52 | 9 – 1/2 | 48 | 8 | 115/60/1 | 600 |

MODEL 125

- This is a basic turntable with footswitch control, a mast and a counter balanced film dispenser which the operator manually raises and lowers. Film tension is adjustable with a simple friction knob on the top of the film roll.

SPECIFICATION TABLE MODEL 125

| Model | Capacity | Load Size | Table Height | Table Diameter | Max RPM | Standard Voltage | Ship Weight |

|---|---|---|---|---|---|---|---|

| ** SW125L40 | 4000 | 52 x 52 | 3 – 1/4 | 60 | 8 | 115/60/1 | 1050 |

| SW125H60 | 6000 | 52 x 52 | 9 – 1/2 | 48 | 8 | 115/60/1 | 750 |

With each step up within these entry level stretch wrappers, there is an increase in operator efficiency and safety. The easier the wrapping job becomes, the faster the operator can work and the quality of the wrapping operation becomes far more consistent. As the volume of wrapping work increases, the savings available to you by model upgrades becomes more and more valuable. Feel free to contact us with any questions you have about our stretch wrap systems.

MODEL 150

- This model consists of a round turntable with mast, a film dispenser with simple friction film tensioner and a powered lift for the dispenser assembly. The operator’s work during the wrapping is reduced to controlling the turntable speed and dispenser lift via switches. There also is a lower limit switch and adjustable upper limit switch for the dispenser lift.

SPECIFICATION TABLE MODEL 150

| Model | Capacity | Load Size | Table Height | Table Diameter | Max RPM | Standard Voltage | Ship Weight |

|---|---|---|---|---|---|---|---|

| ** SW150L40 | 4000 | 52 x 52 | 3 – 1/4 | 60 | 12 | 115/60/1 | 1250 |

| SW150H60 | 6000 | 52 x 52 | 10 – 3/4 | 48 | 12 | 115/60/1 | 1150 |

MODEL 175

- This model is the same as the model 150, except we have added a “geared mechanical prestretch” device that provides 88% prestretch. This means the film is stretched to 188% of its original size for substantial film savings and tighter loads as the film tries to shrink back to its original size.

SPECIFICATION TABLE MODEL 175

| Model | Capacity | Load Size | Table Height | Table Diameter | Max RPM | Standard Voltage | Ship Weight |

|---|---|---|---|---|---|---|---|

| ** SW175L40 | 4000 | 52 x 52 | 3 – 1/4 | 60 | 12 | 115/60/1 | 1285 |

| SW175H60 | 6000 | 52 x 52 | 10 – 3/4 | 48 | 12 | 115/60/1 | 1185 |

* ALL UNITS ARE EQUIPPED WITH FORK POCKETS FOR PORTABILITY.

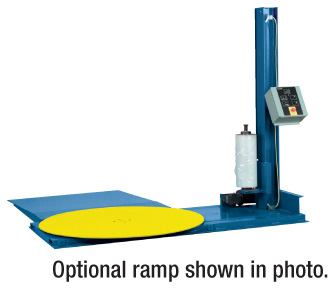

** OPTIONAL RAMPS ARE AVAILABLE FOR ALL LOW UNITS (L40’S).

Call the number below with any questions you have about this stretch wrap turntable.