WHEN DURABILITY MATTERS

1 Year Parts and Labor\10 year, 250,000 Cycle Structural Warranty

Turntables are used for positioning jobs where heavy duty loads must be rotated on a regular basis. There are two basic types of standard duty turntables, non-powered and powered. Positioning turntables are available in low profile and high profile configurations. Inquire about this locking turntable today.

SPECIAL FEATURES

Industrial manual turntable features:

- Lower cost than powered turntables

- These units are manually rotated.

- These units can be rotated in either direction

- All non-powered turntables are low profile.

- Standard platforms are rectangular and round platforms are optional on all models except TML.

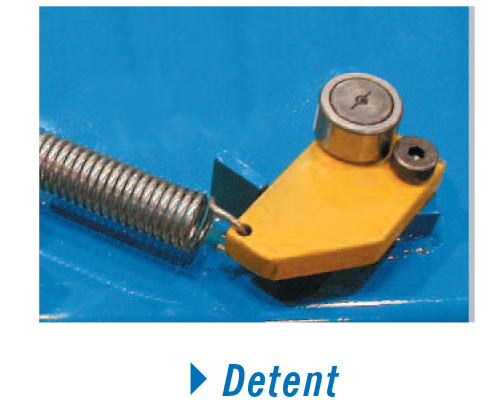

- Rotational limits can be provided via optional detents, locking pins, and hard stops.

- TM platforms are supported by lifetime lubricated roller bearing cam followers.

- TML platforms are supported by lifetime lubricated ball bearing roller.

- Platforms rotate around a lifetime-lubricated kingpin bearing.

- Request a quote for this heavy-duty turntable.

OPTIONAL ROTATIONAL LIMITS FOR MANUAL TURNTABLES: DETENTS, LOCKING PINS AND HARD STOPS

SPECIFICATION TABLE FOR STANDARD DUTY NON-POWERED TURNTABLES

| Edge Load | Platform | Lowered | Roller | Ship | |||

|---|---|---|---|---|---|---|---|

| Model | Capacity | Maximum | Minimum | Maximum | Height | Radius | Weight |

| TML-100 | 1000 | 50 | 30 X 30 | 48 X 48 | 3-1/2 | 9 | 175 |

| TML-200 | 2000 | 50 | 30 X 30 | 48 X 48 | 3-1/2 | 9 | 200 |

| TM-200 | 2000 | 50 | 24 X 24 | 48 X 48 | 3-1/2 | 9 | 350 |

| TM-400 | 4000 | 100 | 24 X 24 | 48 X 48 | 3-1/2 | 10 | 450 |

| TM-600 | 6000 | 200 | 24 X 24 | 48 X 48 | 3-1/2 | 10-1/2 | 550 |

| TM-605 | 6000 | 1150 | 49 X 49 | 60 X 60 | 3-1/2 | 21 | 625 |

| TM-606 | 6000 | 1000 | 61 X 61 | 72 X 72 | 3-1/2 | 21 | 900 |

| TM-607 | 6000 | 1600 | 73 X 73 | 84 X 84 | 3-1/2 | 26 | 1225 |

| TM-608 | 6000 | 1500 | 85 X 85 | 96 X 96 | 3-1/2 | 26 | 1600 |

| TM-804 | 8000 | 1900 | 48 X 48 | 48 X 48 | 3-1/2 | 20-1/2 | 600 |

| TM-805 | 8000 | 1450 | 49 X 49 | 60 X 60 | 3-1/2 | 22-1/2 | 675 |

| TM-806 | 8000 | 1150 | 61 X 61 | 72 X 72 | 3-1/2 | 22-1/2 | 975 |

| TM-807 | 8000 | 1950 | 73 X 73 | 84 X 84 | 3-1/2 | 28 | 1375 |

| TM-808 | 8000 | 1750 | 85 X 85 | 96 X 96 | 3-1/2 | 28 | 1730 |

| TM-1005 | 10000 | 1600 | 49 X 49 | 60 X 60 | 3-1/2 | 23 | 750 |

| TM-1006 | 10000 | 1250 | 61 X 61 | 72 X 72 | 3-1/2 | 23 | 1080 |

| TM-1007 | 10000 | 2100 | 73 X 73 | 84 X 84 | 3-1/2 | 29 | 1470 |

| TM-1008 | 10000 | 1900 | 85 X 85 | 96 X 96 | 3-1/2 | 29 | 1920 |

* CLICK ON THE MODEL NUMBER IN THE CHART TO VIEW PRODUCT SHEET

Call the number below with any questions you have about our industrial manual turntable.