These are our largest sized Disappearing Dock lifts. Recessed dock scissor lifts are sized to handle any mobile material handling equipment you may have. They also provide dock to ground access. Inquire about these loading dock lifts for sale today!

SPECIAL FEATURES

- Cylinders are mounted directly to platform corners to eliminate platform deflection during load transfer.

- All models are equipped with a hinged bridge with a pull back chain.

- All of the electrical controllers are Underwriters Laboratories approved assemblies.

- Each hydraulic dock lift is washed with phosphoric acid, fully primed and then finished with baked enamel.

- All cylinders are machine grade with clear plastic return lines & internal mechanical stops.

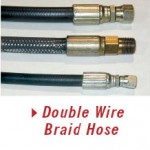

- All pressure hoses are double wire braid with JIC fittings.

- Reservoirs are mild steel.

- These units conform to all applicable ANSI codes.

FEATURE DETAILS

SPECIFICATION TABLE FOR 4000 SERIES LIFTS

| Model | Lift Capacity | Axle Cap. Ends | Axle Cap. Sides | Platform Size | Lowered Height | Travel | Speed FPM | Power Unit HP | Ship Weight |

|---|---|---|---|---|---|---|---|---|---|

| 4100 | 12000 | 9600 | 8400 | 6′ x 10′ | 16-1/2″ | 58″ | 7 | 5 | 5500 |

| 4110 | 12000 | 9600 | 8400 | 6′ x 11′ | 16-1/2″ | 58″ | 7 | 5 | 5700 |

| 4120 | 12000 | 9600 | 8400 | 6′ x 12′ | 16-1/2″ | 58″ | 7 | 5 | 5900 |

| 4130 | 12000 | 9600 | 8400 | 7′ x 10′ | 16-1/2″ | 58″ | 7 | 5 | 5800 |

| 4140 | 12000 | 9600 | 8400 | 7′ x 11′ | 16-1/2″ | 58″ | 7 | 5 | 6050 |

| 4150 | 12000 | 9600 | 8400 | 7′ x 12′ | 16-1/2″ | 58″ | 7 | 5 | 6300 |

| 4160 | 12000 | 9600 | 8400 | 8′ x 10′ | 16-1/2″ | 58″ | 7 | 5 | 6300 |

| 4170 | 12000 | 9600 | 8400 | 8′ x 11′ | 16-1/2″ | 58″ | 7 | 5 | 6600 |

| 4180 | 12000 | 9600 | 8400 | 8′ x 12′ | 16-1/2″ | 58″ | 7 | 5 | 6900 |

| 4200 | 15000 | 12000 | 10500 | 6′ x 10′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 5800 |

| 4210 | 15000 | 12000 | 10500 | 6′ x 11′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 6000 |

| 4220 | 15000 | 12000 | 10500 | 6′ x 12′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 6200 |

| 4230 | 15000 | 12000 | 10500 | 7′ x 10′ | 16-1/2″ | 58″ | 8 | 7 -1/2 | 6100 |

| 4240 | 15000 | 12000 | 10500 | 7′ x 11′ | 16-1/2″ | 58″ | 8 | 7 -1/2 | 6350 |

| 4250 | 15000 | 12000 | 10500 | 7′ x 12′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 6600 |

| 4260 | 15000 | 12000 | 10500 | 8′ x 10′ | 16-1/2″ | 58″ | 8 | 7 -1/2 | 6600 |

| 4270 | 15000 | 12000 | 10500 | 8′ x 11′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 6900 |

| 4280 | 15000 | 12000 | 10500 | 8′ x 12′ | 16-1/2″ | 58″ | 8 | 7- 1/2 | 7200 |

| 4300 | 18000 | 14400 | 12600 | 6′ x 10′ | 18″ | 58″ | 8 | 7- 1/2 | 6400 |

| 4310 | 18000 | 14400 | 12600 | 6′ x 11′ | 18″ | 58″ | 8 | 7- 1/2 | 6600 |

| 4320 | 18000 | 14400 | 12600 | 6′ x 12′ | 18″ | 58″ | 8 | 7 -1/2 | 6800 |

| 4330 | 18000 | 14400 | 12600 | 7′ x 10′ | 18″ | 58″ | 8 | 7- 1/2 | 6700 |

| 4340 | 18000 | 14400 | 12600 | 7′ x 11′ | 18″ | 58″ | 8 | 7- 1/2 | 6950 |

| 4350 | 18000 | 14400 | 12600 | 7′ x 12′ | 18″ | 58″ | 8 | 7- 1/2 | 7200 |

| 4360 | 18000 | 14400 | 12600 | 8′ x 10′ | 18″ | 58″ | 8 | 7 -1/2 | 7200 |

| 4370 | 18000 | 14400 | 12600 | 8′ x 11′ | 18″ | 58″ | 8 | 7-1/2 | 7500 |

| 4380 | 18000 | 14400 | 12600 | 8′ x 12′ | 18″ | 58″ | 8 | 7 -1/2 | 7800 |

| 4400 | 20000 | 16000 | 14000 | 6′ x 10′ | 20″ | 58″ | 8 | 7- 1/2 | 6900 |

| 4410 | 20000 | 16000 | 14000 | 6′ x 11′ | 20″ | 58″ | 8 | 7 -1/2 | 7300 |

| 4420 | 20000 | 16000 | 14000 | 6′ x 12′ | 20″ | 58″ | 8 | 7 -1/2 | 7900 |

| 4430 | 20000 | 16000 | 14000 | 7′ x 10′ | 20″ | 58″ | 8 | 7- 1/2 | 7000 |

| 4440 | 20000 | 16000 | 14000 | 7′ x 11′ | 20″ | 58″ | 8 | 7 -1/2 | 7400 |

| 4450 | 20000 | 16000 | 14000 | 7′ x 12′ | 20″ | 58″ | 8 | 7- 1/2 | 8000 |

| 4460 | 20000 | 16000 | 14000 | 8′ x 10′ | 20″ | 58″ | 8 | 7-1/2 | 8000 |

| 4470 | 20000 | 16000 | 14000 | 8′ x 11′ | 20″ | 58″ | 8 | 7 -1/2 | 7800 |

| 4480 | 20000 | 16000 | 14000 | 8′ x 12′ | 20″ | 58″ | 8 | 7- 1/2 | 8100 |

General:

These hydraulic dock lifts have cylinders in direct thrust to all four platform corners, which provides maximum rigidity. This design approach for heavy fork truck applications eliminates the spring board effect of platform overhang on lifting scissors in the raised position. When a fork truck passes onto our lift from a semi trailer, you will observe an inch or more of vertical movement of the trailer and no discernable movement of the lift. The recessed scissor lifts are plumbed for anti-interflow between cylinders when the unit is at rest. These are the most rugged and rock solid lifts in the industry. Call 1-800-843-3625 with any questions you have about our recessed hydraulic dock lifts.

You may also like our 3000 Series Recessed Loading Dock Scissor Lifts.